Check valves are usually installed in the pipeline to prevent backflow. A check valve is basically a one-way valve in which the flow can flow freely in one direction, but if the flow turns, the valve will be closed to protect the piping, other valves, pumps, etc. If the flow is diverted without a check valve installed, a water hammer may occur. Water hammer often occurs with extreme force and can easily damage pipes or components.

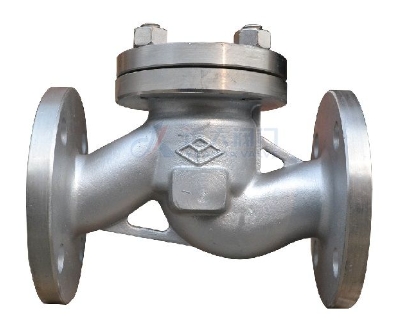

Check Valve

Check Valve Definition

A check valve is a fundamental component in fluid systems, playing a crucial role in regulating the flow of liquids or gases. This simple yet essential device prevents backflow and maintains the desired direction of fluid movement. Understanding the function and types of check valves is essential for engineers, manufacturers, and anyone involved in fluid control systems.

How Does a Check Valve Work?

Check valves operate on a straightforward principle: allowing fluid to flow in one direction while preventing reverse flow. The valve consists of a movable mechanism, often a disk or a flap, and a body with an inlet and an outlet. When the fluid flows in the intended direction, the mechanism opens, enabling the fluid to pass through. However, when there is a reversal in flow, the mechanism closes, preventing the fluid from going backward.

Types of Check Valves

Swing Check Valves

One of the most common types is the swing check valve. It features a hinged disk that swings open and closed. When the fluid flows forward, the disk swings open, allowing passage. If there is a backflow, the disk swings shut, preventing the reverse movement of the fluid.

Ball Check Valves

Ball check valves use a ball as the movable mechanism. When the fluid flows forward, the ball is pushed away from the seat, permitting the flow. In the case of backflow, the ball returns to the seat, blocking the reverse flow.

Diaphragm Check Valves

Diaphragm check valves utilize a flexible diaphragm as the moving part. The diaphragm allows forward flow by flexing away from the seat. When there is a change in direction, the diaphragm returns to its original position, blocking the flow.

Applications of Check Valves

Check valves find applications in various industries, including oil and gas, water treatment, pharmaceuticals, and more. They are crucial in preventing damage to pumps and other downstream equipment caused by backflow. In plumbing systems, they maintain water pressure and prevent contamination.

Factors to Consider When Choosing a Check Valve

When selecting a check valve, several factors come into play. These include the type of fluid, pressure requirements, temperature conditions, and the overall system design. Understanding these factors is crucial for ensuring the proper functioning of the check valve within a specific application.

Maintenance and Troubleshooting

While check valves are relatively simple devices, proper maintenance is essential for their optimal performance. Regular inspection ensures that the moving parts are functioning correctly and that there are no obstructions in the flow path. Troubleshooting may involve checking for leaks, assessing the condition of the valve components, and addressing any issues promptly.

Conclusion

In conclusion, check valves play a vital role in fluid systems by preventing backflow and ensuring the unidirectional flow of liquids or gases. Understanding the types, applications, and factors influencing the selection of check valves is crucial for those involved in designing and maintaining fluid control systems. Regular maintenance and troubleshooting contribute to the longevity and efficiency of these essential components.

For more information about check valves or to inquire about a specific application, feel free to contact us. As a reliable supplier of fluid control solutions, we are here to assist you in finding the right check valve for your needs.